Written by: Mısra Adıyaman, Quality Control Engineer, Bastak Instruments, Turkey

The strategic importance of wheat, the main ingredient of bread, has remained unchanged throughout the ages. The main factors determining the bread quality of wheat, which is the cornerstone of bread production, are ash content, protein content and quality. The difference in quality observed in breads made from wheat with the same protein content can be attributed to the unique properties of protein. The amount and quality of protein in wheat and flour are among the most important factors determining their intended use. Therefore, accurate, reliable and rapid determination and testing of protein quantity and quality during the transformation of raw material into final product is an important point for both producers and consumers.

Zeleny sedimentation value

In order to obtain the desired qualities in the final product and to determine the protein quality and gluten, it is necessary to determine the Zeleny Sedimentation value, which is directly proportional to the bread volume. Due to the presence of proteolytic activity in the secretions of the swarm and the vine, which adversely affect the quality of wheat, they cause deterioration in dough quality and properties during fermentation.

In the classification of wheat and the characterization of wheat flour, it is necessary to measure the sedimentation value along with protein and gluten content. Among these quality parameters, there is a linear mathematical relationship between protein content and wet gluten. It is known that the Zeleny sedimentation value in flour is related to the composition of wheat protein and is related to the amount of protein.

The sedimentation value is influenced by genetic factors and environmental conditions; however, genetic factors have a greater influence than environmental conditions. The Zeleny sedimentation value is influenced by genetic factors and environmental factors, especially the negative effects caused by the pest, the common fly.

Bastak's solution

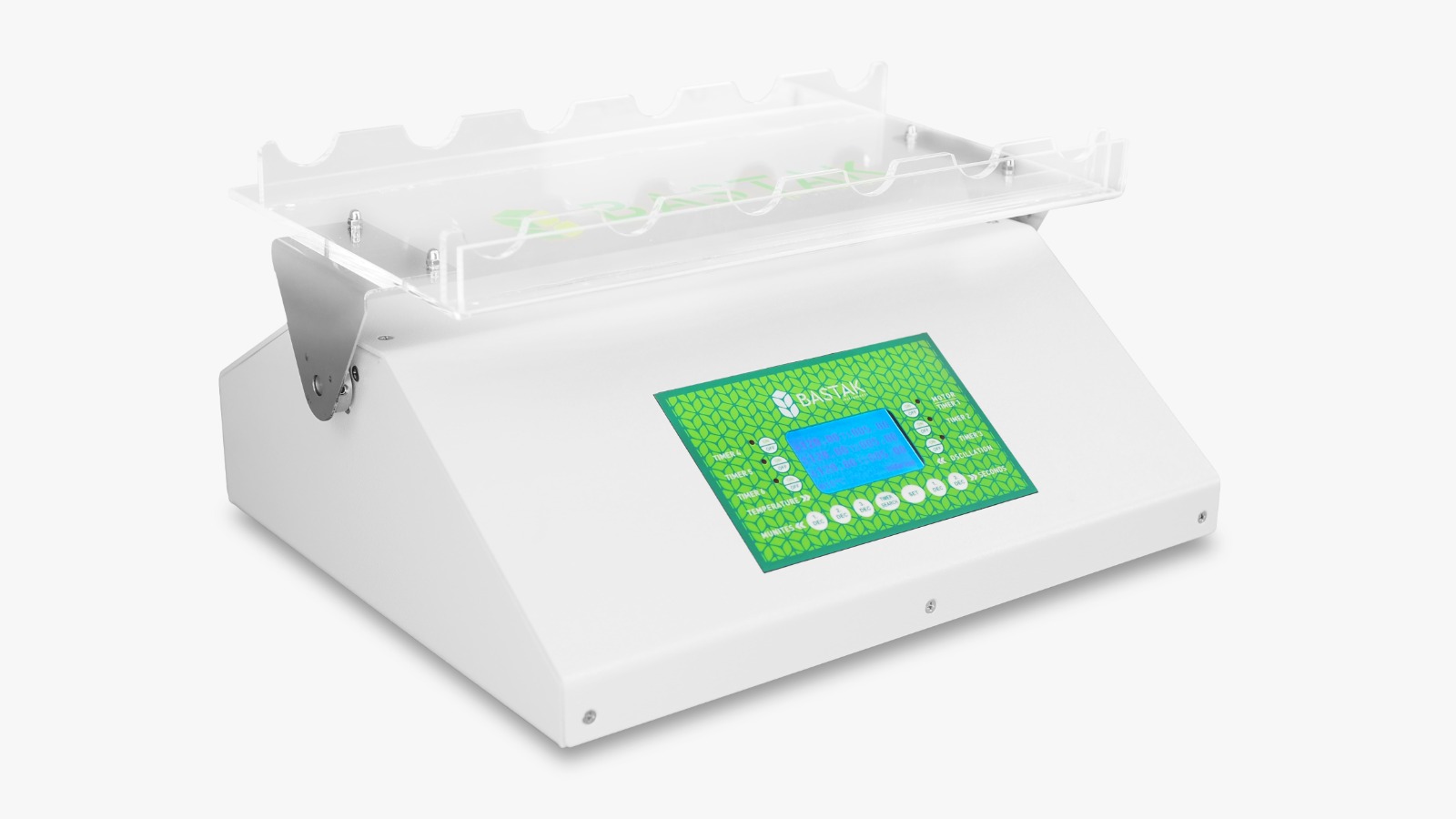

In Baştak's factory, which has a closed area of 7,000 square meters, the Sedimentation 3100 (Zeleny) 3100 model, which is equipped with the latest technology and is considered the best in the world in terms of machine quality, is produced. It is used to determine the pasta and bread quality and insect damage of samples obtained from commercial flour, wheat flour, whole wheat flour, durum wheat flour, bulgur, vital gluten, noodle and semolina in accordance with international standards.

The device is capable of performing tests using physicochemical methods. While the protein quality of the sample is analyzed in the standard sedimentation test, the Delayed (modified) Sedimentation test is used to check the amount of protease enzyme in bakery products due to the damage of the insect. Protease enzyme can break down proteins and negatively affect the appearance and gas retention quality of the final product. Bastak brand 3100 model sedimentation instruments can perform both traditional sedimentation tests and modified sedimentation tests.

With a wide range of samples including red, white and durum wheat as well as commercial flour, wheat flour, whole wheat flour, durum wheat flour, bulgur, vital gluten, vermicelli and semolina, the instrument offers users a unique analysis experience. Color graphic LCD display, 13 function buttons, extensive function capabilities, microprocessor control, membrane technology, 40 revolutions per minute and 30° working angle, all in compliance with the ICC Standard.